Summary

A specialized textile-testing machine measures the thickness of a moving textile web continuously and in real time. As the web passes over a roller, a precision analog inductive sensor, positioned directly above the roller, rests lightly on the top of the web. By sensing the distance through the material to the roller, the sensor measures the thickness of the web.

Customer Values

-

Accurate high-speed measurement of fast-moving material

-

Discrete raw-data output with exceptional resolution

-

Real-time process monitoring and adjustment

-

Highly reliable, cost-effective solution

Specific Product Advantages

-

Continuous measurement with current or voltage analog signal

-

Precisely calibrated, near-linear output

-

High-speed measurement with an exceptional resolution

Customer Application

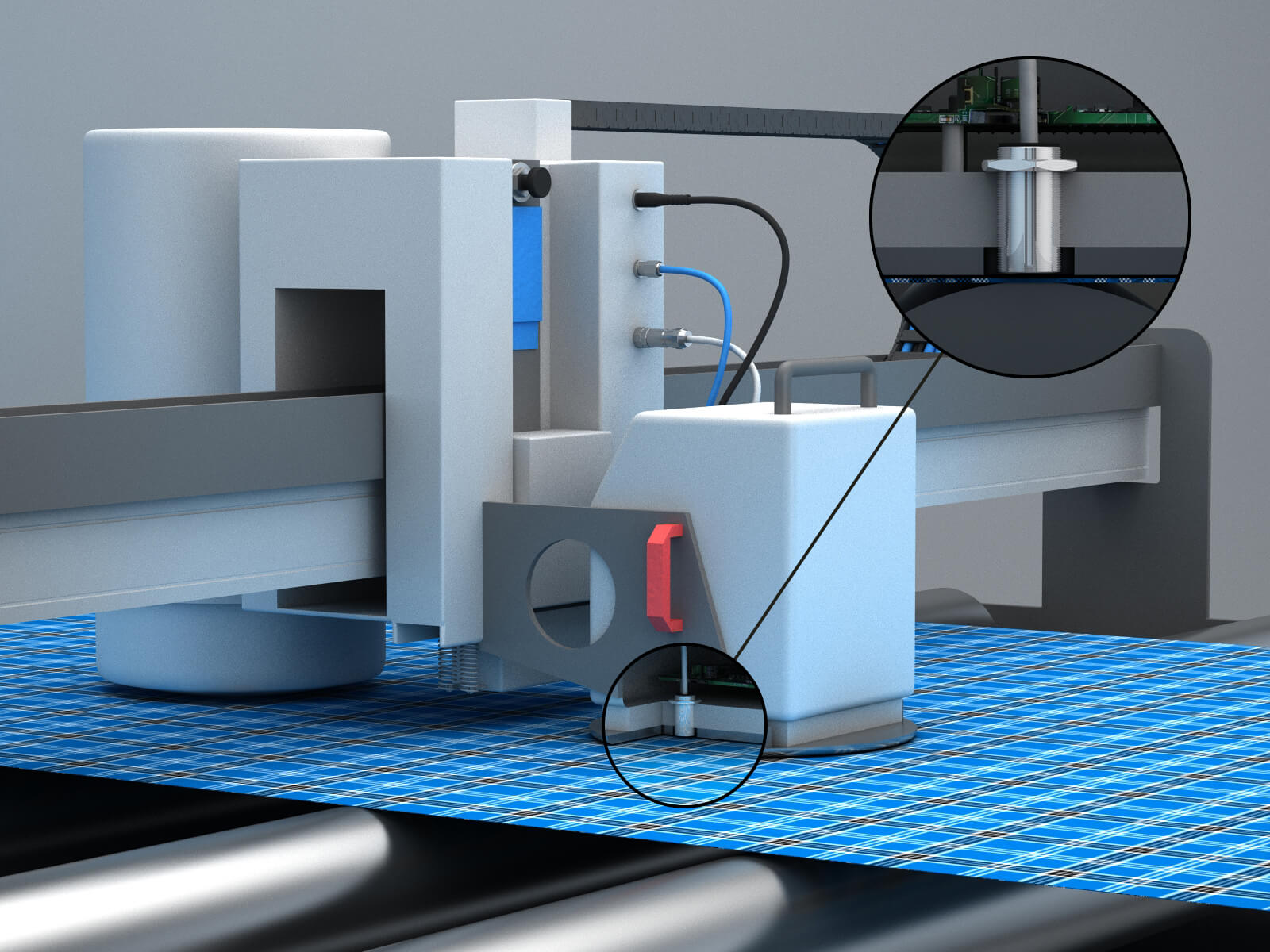

During the manufacture of textiles and fabrics, measuring the thickness of the material immediately after its formation allows real-time adjustments to the production process. A Swiss manufacturer of specialized textile-testing machines requires a high-accuracy sensor to measure the thickness of a continuously produced sheet, or web, of material moving at up to 5m/s (16.4fps).

Measurements are required across the full width of textile webs up to 4m (13ft) wide. A transverse-axis carriage lies immediately above a fixed roller; a sensing head, mounted on the carriage, traverses the width of the web as it passes over the roller. A precision sensor must provide real-time measurements in the range 0 to 4mm with a resolution of 0.02mm (0.0008”) or better.

High-frequency measurement is also required to accommodate the speed and width of the moving web. A continuous analog output is necessary as conventional digital sensors do not provide the required resolution.

Customer Solution

Contrinex Analog Output inductive sensors are highly accurate and provide continuous voltage or current outputs; the range is ideal for this application. Quasi-embeddable with a chrome-plated brass body and PBTP sensing face, an M18-diameter sensor allows sensing distances up to 10mm (0.4”) with resolution in the µm range.

The sensor, mounted in the sensing head, moves rapidly back and forth across the web and senses through the material of the web as it feeds over the roller. It measures the distance from its sensing face – which lies a known distance from the bottom face of the head – to the top surface of the roller. It delivers a precisely calibrated, near-linear, discrete output in the range 0 to 10V or 4 to 20mA.

This Contrinex inductive sensor has a sealed cable entry, ensuring fit-and-forget capability during extended periods of operation, and connects with the machine’s control system via a flexible PUR-sheathed cable. Using a custom-configured software interface, output data is displayed numerically and graphically on a PC screen, allowing real-time adjustment to the production process when necessary.

Contrinex Analog Output sensors deliver a cost-effective solution that satisfies the customer’s requirements for accurate high-speed measurement with an exceptional resolution.

Relevant industries

Machine tool

Packaging

Logistics

Material handling

Textile

Printing

Metal sorting

Quality control

Vibration monitoring

Discover the full range: https://www.contrinex.com/en-ch/collections/inductive-analog-output