Summary

A German manufacturer of leather products uses non-contact access-control barriers to improve workplace ergonomics and increase productivity during the drum-dyeing process. A rugged optoelectronic access-control barrier is mounted directly in front of each dyeing drum, preventing the drum from rotating and stopping the operating cycle immediately if it detects any body part or person in the working area.

Customer Values

- Improved workplace ergonomics without compromising safety standards

- Increased productivity arising from unimpeded loading and unloading

- No changes required to cleaning process as sensors are sealed to IP69K

- Industry-standard interface requires little modification to control systems

Specific Product Advantages

- IP69K protection allows operation in hostile environments

- Non-contact operating principles with manual or automatic restart

- Excellent safety rating to EN ISO13849-1 (Category 4, PL e) and IEC 64196-1 and -2 (Type 4)

- Rugged optoelectronic sensor with aluminum housing and metal cable connector

Customer Application

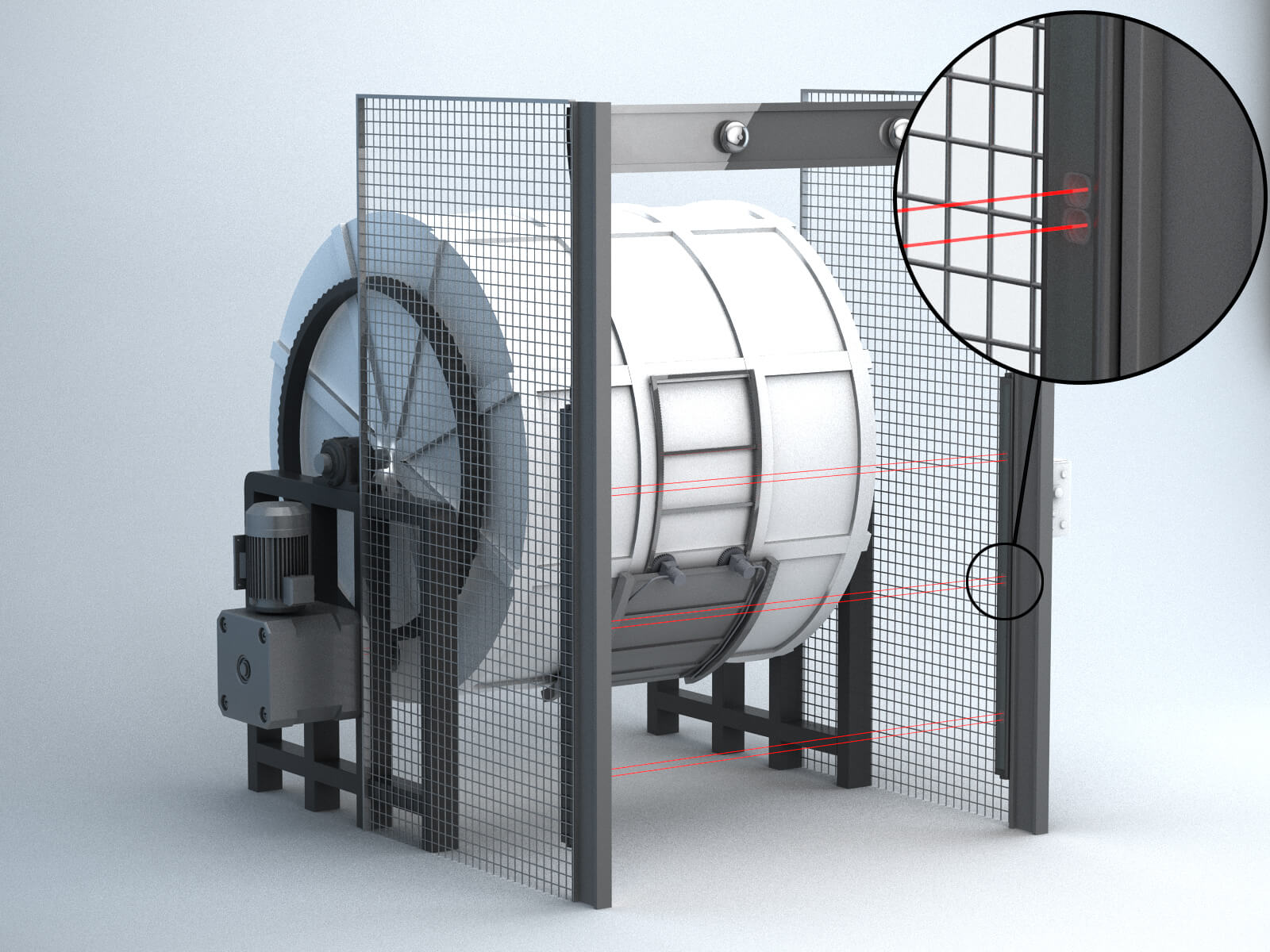

Drum dyeing is an important process in the manufacture of leather goods. During operation, a large metal dyeing drum rotates continuously, with production staff relying on steel-mesh safety guards to prevent contact with moving parts. The drum holds 1800 kg of leather, and between dyeing cycles it is unloaded and reloaded manually.

At the end of each cycle, the safety guards are raised to allow the operator to unload the drum. The low ceiling in the dyeing area limits the height to which the guards can be raised, preventing operators from working comfortably. Productivity is suboptimal and the workplace ergonomics are unsatisfactory.

The company requires an alternative safety guard that maintains safe operation and allows unobstructed loading and unloading. It must be simple, space-saving and operate reliably in the production environment. Specifically, the new guard must withstand the hot-water and detergent spray used to clean the drum after each cycle.

Customer Solution

Safetinex YCA-50R/S4-4400-G012-69K non-contact access-control barriers from Contrinex are in the highest safety categories of EN ISO13849-1 (Category 4, PL e) and IEC 64196-1 and -2 (Type 4) and are ideal for this application. Manufactured with rugged aluminum housings fully sealed to IP69K, these units easily withstand the hot-water and detergent spray used during the cleaning phase of the process.

Configured with Contrinex YRB-0131-241 safety relays, Safetinex multi-beam photoelectric sensors offer exceptional standards of protection. Industry-standard PNP normally-open configuration allows connection to the customer’s control system via a flexible PVC sheathed cable with a metal cable connector.

Each dyeing machine forms a U-shape and the light barrier protects the front open side, an area two meters wide. Detection height is 1.2 meters and if a foreign body enters during any part of the operating cycle, the system brings the drum to an immediate halt. Either automatic or manual restart is possible once the area is clear.

The new sensors take up much less space than the mechanical guards they replaced, improving workplace ergonomics. Loading and unloading is no longer impeded, increasing productivity while maintaining safety standards. Additionally, removal of the mesh guards allows an unobstructed view of the machine during operation.